Aqara switches are somewhat very common zigbee light switches. I moved to these a few years ago and they worked without an issue up until about now. And now, guess what: Mechanics failed. So I decided to document 2 different ways of fixing them in this very post

The problem

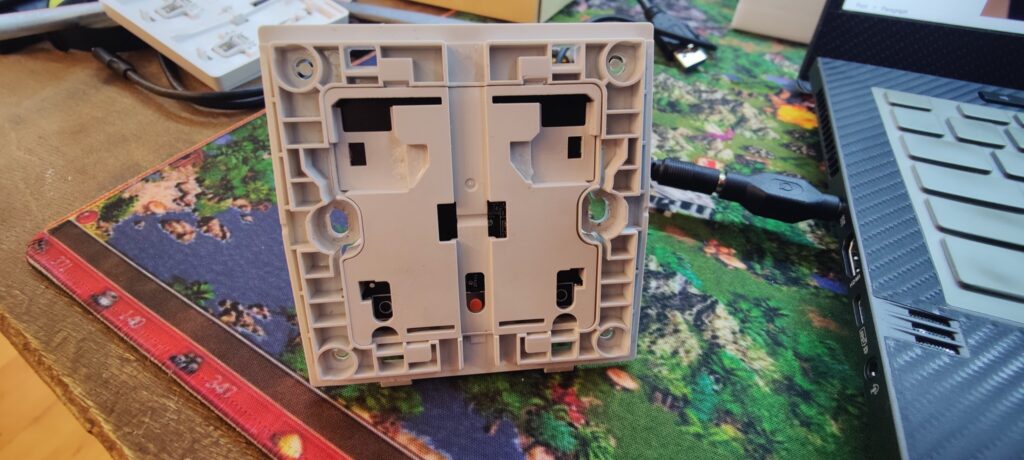

As you might’ve guessed from the photo above – the plastic spring elements that press the push button on the switch fail and break away after about a year or two, depending on the usage. So, if you don’t like the idea of adding more plastic to the nearest landfill, you have 2 options.

Solder/move the button to the nearby unpopulated footprint

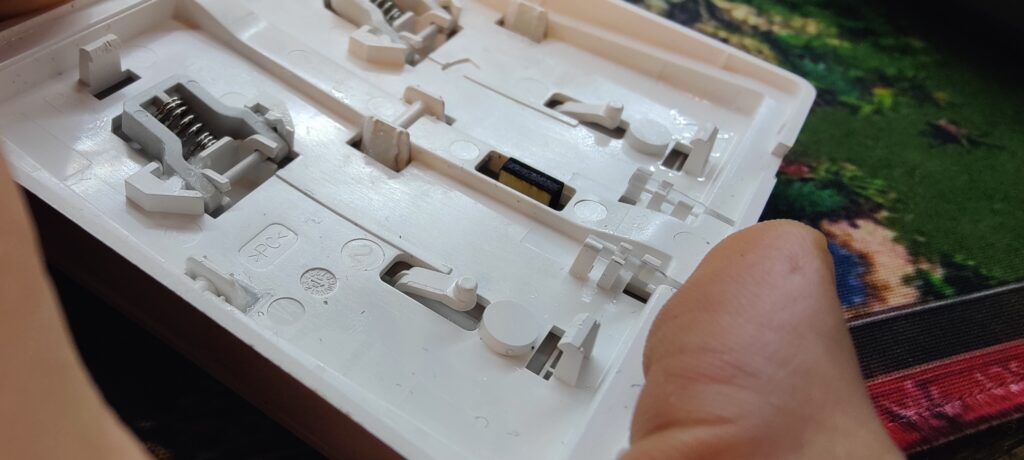

The switches come in variants of single and double. But the PCB is the same and has 3 footprints for 3 buttons. The single switch has the central one populated, while the double switch has the 2 buttons on the sides populated and the middle one missing.

The plastic cover has 3 plastic spring elements attached for all 3 possible buttons that looks like a very weird solution. But it’s quite good for us.

And here’s the catch. One of the side buttons is wired to the same GPIO’s as the central button. So if you move the central one or just add another switch you can use the spring elements on the cover that are still intact for another year or two.

Unfortunately, I didn’t take photos of the whole procedure, but it’s quite easy provided that you know your way around with a multimeter.

The second way

This one will require a laser or a 3d-printer. I used my laser for this hack. Cut/print a 7x8x4mm cube. I used 4mm plywood and some glue after.

Afterwards just assemble and voila – it’s working.

If you don’t want the button to break fast after this mod, either make you plywood brick a little lower (this will need manual tuning, depending on the size of the cut) or make it deliberately lower and attach something soft at the top. Printing with rubber-like filament may be an option, but I didn’t have it around to try.

Wow, This post really helped me with it. I’m not very good at repairing these kinds of things