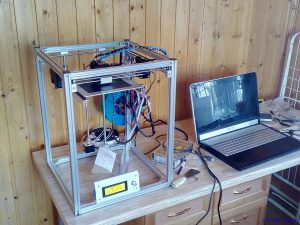

I recently got myself a new toy, so to speak. It’s a brand new Flying Bear P902 3d printer. For it’s price (~300$) it’s an awesome machine and is way better made than my old 2nd gen Solidoodle. So I’ll be posting a series of hacks that I had to do to work comfortably with it and this is the first post in series, starting with this one.

Not so ready to print

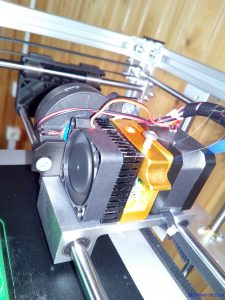

What I liked most about the machine is that it’s mostly metal, with very little plastic parts. Only X carriages and some limit switches are plastic. The extruder is no exception and it is mostly metal with two fans. So I assembled it, plugged a fresh roll of ABS filament and…

It looks like the filament was scratching against the aluminum hole in the assembly and that resulted in a lot of dust accumulating eventually failing the print.

It looks like the filament was scratching against the aluminum hole in the assembly and that resulted in a lot of dust accumulating eventually failing the print.

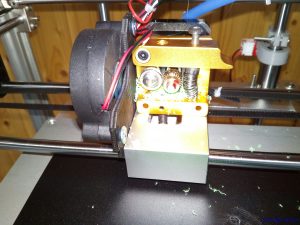

To fix this all I had to do was – remove the fan to get access to the extruder gear, unscrew the pulley to the left of the extruder gear, swap the disc and the pulley and reassemble.

Once I did that the filament was perfectly aligned and I could print with without any problems

Once I did that the filament was perfectly aligned and I could print with without any problems